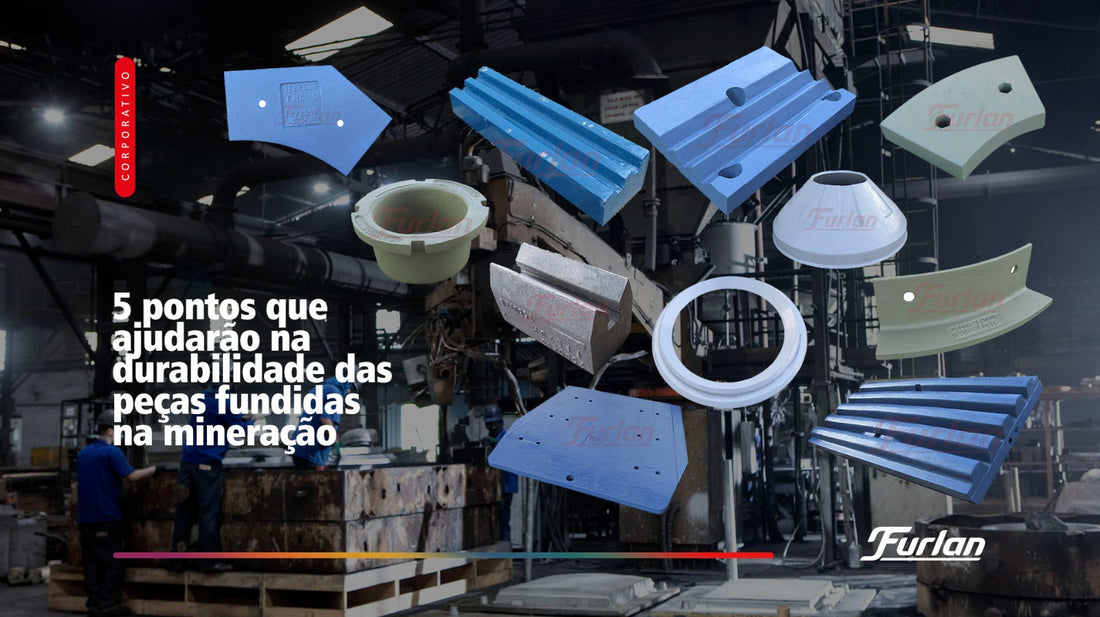

5 points that will help in the durability of castings in mining

Share

The durability of castings is one of the main indicators in the mining industry. Possible breakages or premature wear are challenges that, when overcome, bring success to the company.

The mining company's delivery deadlines to its customers are met. Costs are reduced. This results in greater business profitability and increased chances of new sales.

That's why we're back to the topic today. As a reminder, on April 12th and 20th, the Minerando blog brought some very explanatory content about the issue of quality in mining parts and the factors that influence this quality.

Now, the Furlan team addresses important information for greater durability of parts. We also point out the importance of choosing a supplier that has strict quality standards.

Check it out.

What information about the deposit helps in choosing the casting?

When we talk about parts used in mining equipment, we can mention hammers, casings, mantles and screws – among others. However, what is the best type of alloy to use in a hammer? Can the alloy I use today be improved?

The answers will depend on fundamental characteristics of the production scenario, such as details about the type and abrasiveness of the rock to be processed.

This information is shared in a process in which the mining company seeks a supplier that adopts the best quality standards. It should also be evaluated by a mining company that aims to manage parts in a way that reduces costs with downtime and unscheduled stops in the mine, or combats excess material in stock for possible repairs to machines.

The Furlan team points out that there is a lot of information that is crucial. The group of engineers and technicians, in addition to the Commercial area, chose to mention five points.

Let's get to know this important checklist.

1. Make it clear what type of ore is to be processed.

The type of ore can significantly affect the durability of parts. This is because some ores are often more abrasive than others, which can cause parts of mining equipment to wear out more quickly.

Therefore, it is important to know the type of ore to be processed and choose parts with adequate strength and durability.

2. Assess the abrasiveness of the rock.

In simple terms, we can explain abrasiveness as a measurement of a material's ability to wear down other materials. In general, more abrasive materials require more resistant and durable parts.

Therefore, it is important to evaluate the abrasiveness of the ore and choose pieces with the appropriate hardness and resistance. This is because we often also have to check the crushability of the rock, among other characteristics. This influences the type of alloy to be used.

3. Know the conditions of the deposit well.

This is another point that, in many situations, affects the durability of the parts. For example, the presence of water or other liquids can corrode the parts. Dust or fine particles are, in some cases, responsible for accelerating wear.

Therefore, it is important to evaluate the conditions of the deposit and choose pieces that are resistant to the agents present in the environment.

4. What type of equipment is it?

Each piece of equipment has its own requirements in terms of parts and components. Therefore, it is important to choose parts that are suitable for the equipment in question, considering its specificities and requirements.

5. How often is maintenance performed and how is it performed?

The frequency and quality of equipment maintenance are also important for parts to last longer. Parts that are well cared for and maintained can last longer than those that do not receive proper attention.

Therefore, it is important to invest in regular, quality maintenance of equipment and its parts.

Dialogue generates greater efficiency and productivity

Let's base our analysis on mining companies that are successful and improve their production and management performance. The data above allows us to choose parts that are resistant and durable. In this scenario, operations are more efficient and productive.

There is a Furlan client, whose strength is the production of aggregates, which achieved a 15% cost reduction in the budget allocated to parts by implementing practices that include this checklist.

It became clear then that advances in the durability of castings are, in most cases, related to the supplier chosen by the mining company. Máquinas Furlan combines experience and continuous improvement to offer the market the best options.

The company has been in business for 61 years. Over time, it has become one of the leading specialists in each stage of the production of a machine or wear part. Steel manufacturing, heat treatment, machining, boilermaking and equipment assembly are all carried out in-house.

Some of the parts are used to equip Furlan's own machines for crushing, grinding and screening minerals. Even among the items produced by national and international competitors, Furlan is gaining market share by presenting a collection of over 12 thousand models of these parts. Thus, the customer has a large number of items available, as the page on our website.

Now that we have presented the main benefits, it is time for you to talk to the Furlan team to find out how to obtain greater durability from the castings of your mining machine.

Click here and talk to us.

Now, do you want to know more? Check out these two pieces of content related to durability.

. Factors that influence the quality of parts - Click here

. Durable equipment and parts - discover the benefits here