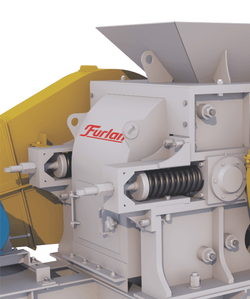

ROLLER MILL

Furlan Roller Mills are designed and manufactured to support the production of fines. They are used in grinding materials of low, medium and high hardness and abrasiveness, such as: mineral and vegetable coal, bauxite, graphite, kyanite and limestone in general, refractories, shot, feldspar, among others. They are manufactured in various sizes to best meet customer needs.